Aiming to be an

only-one-supplier

utilizing Wing Field's

unique strengths

Supporting customers with integrated production

Our integrated production starts after we receive drawings and specifications. We take care of everything, from material procurement to planning, jig production, parts machining, special processes, and assembly. Our Equipment Business supports all steps from design and development to manufacturing, sales, and after-sales service.

Ensuring world-standard quality

Wing Field has acquired the latest “JIS Q 9100:2016”, the quality management standards for aviation, space and defense organizations, and offers attractive products and services under the specified rules so that we can continue to meet expectations and trust.

Extensive range of special equipment

Our factory is equipped with extensive special equipment required for producing aircraft components, including fully automated surface treatment equipment, fluorescent penetrant testing equipment, heat treatment furnaces, autoclaves, and auto-riveters.

01

Metal

Component

Business

The advanced sheet metal processing technology we have developed over the years is a key element that makes integrated production of aircraft component manufacturing possible. The attentive manufacturing by our skilled engineers supports our competitiveness. In recent years, we have introduced new equipment to improve productivity while maintaining and updating existing equipment. Workers and machines collaborate with their respective strengths to manufacture products that meet our customers' needs. We manufacture components for Boeing, Embraer, Bombardier, HondaJet, and others, and aircraft components for Japan's Ministry of Defense.

NC machine

NC (numerical control) processing machines are utilized for highly precise processing.

Finishing work

An orbital sander is used to remove surface scratches and burrs and finish the component surface.

Rubber press molding

Convex molds and rubber are used to press components.

Heat treatment

Components are heat-treated to attain the strength specified in the designs.

Coating

Metal components are coated to prevent corrosion.

Surface treatment

The surface of metal components is treated with fully automated equipment to prevent corrosion.

02

Composite

Material

Component

Business

Our composite molding technology supports our activities in diverse fields, ranging from industrial products and aircraft to space equipment and, more recently, drones and aerial vehicles. We use our years of expertise and advanced technologies and equipment, including autoclaves, clean rooms, automatic cutting machines, and NDI equipment, to produce high-quality products.

Composite materials that are highly rigid and lightweight help reduce fuel consumption and contribute to creating a carbon-neutral and economical society.

Inside the clean room

The work is carried out in a controlled environment where temperature, humidity, and cleanliness are regulated.

Automatic cutting machine

After the material is designed in 3D, it is developed into a 2D shape and cut using specialized equipment.

Lay-up operation

The composite materials are laid out along the mold (lamination mold) to ensure the specified quality in the design.

Autoclave

The laminated composite material is heated and pressurized to produce products with the required strength for aircraft.

03

Structural

Assembly

Business

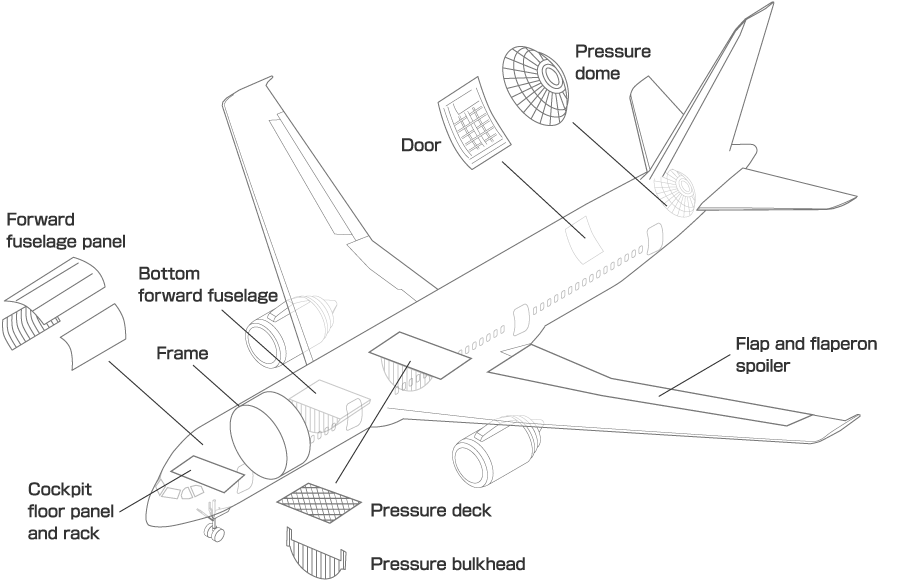

Aircraft, which carry many lives, must not have even the slightest defect in hole diameter or misalignment of holes. Assembly work demands a high level of accuracy and reliability, and it requires highly skilled technical capabilities.

In our Structural Assembly Business, we assemble frames, decks, and moving blades for commercial airliners, as well as panels and decks used in Ministry of Defense aircraft. We also maintain and repair various aircraft components for the Ministry of Defense, including moving blades, seats, and radomes.

Frame assembly

Components are fastened using a riveter called a squeezer.

Bolt fastening work

Two workers fasten the bolts together.

Auto-riveter

The riveter machine drills a hole at the marked section and fastens the components together.

Aircraft moving blade

assembly

Drilling, fastening, and painting of the moving blade are performed.

04

Equipment

Business

Wing Field's long history as an aircraft seat manufacturer started in 1967, developing and manufacturing seats for helicopters, commercial aircraft, and aircraft for the Ministry of Defense. For the Ministry of Defense, we have manufactured seats with a shock-absorbing function to protect lives from impact loads of 50G, seats equipped with bulletproof plates, etc. We also manufacture seats for transport aircraft, patrol aircraft, and rescue flying boats for the Ministry of Defense, as well as seats for helicopters, and have the largest domestic share.

Order receipt,

design development, and

production planning

The material information and processing methods required for the product are studied based on the design data.

Sewing

We also sew cloth covers for seat surfaces, etc.

Seat assembly

The frame and panels of the backrest section are assembled, drilled, and fastened together.

Component Assembly

The components are drilled and fastened to complete the aircraft seat assembly.